HULL CLEANING / GROOMING

A well-cleaned and property maintained hull results in huge fuel savings. Hull cleaning in the olden times took on the form of paint coatings having cuprous oxide. In 1974, a new form of self polishing treatment known as “TBT” was introduced. But, because of the environmental hazards this treatment posed, it had to be discontinued. Nowadays, a different form of antifouling is used which is hospitable to fouling organisms and it only requires regular underwater cleaning.

Since the new coating material relies chiefly on texture, underwater cleaning becomes all the more important. Modem marine coatings include a range of non-toxic, low surface energy materials based on nonstick frying pan technology. Therefore, in case of a hull being fouled, it is wise to preserve the entire antifouling material and all it takes is providing it proper protection and cleaning.

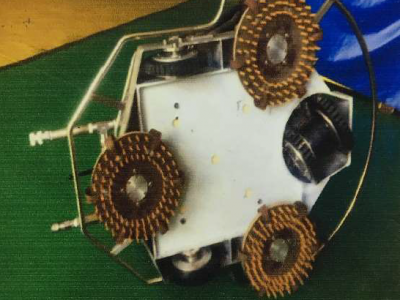

We are equipped with second-generation hull cleaning equipment. The underwater hull cleaning vehicle is the first of its kind in Pakistan. This device is based on Three counter rotating brushes capable of creating a suction force of several hundred kilograms.

Such an enormous force is counter-balanced by an in-built mechanism that transfers the load on to the chassis instead of the ship. This largely facilitates the vehicle converting it into a highly effective machine for cleaning marine growth, fouling and all kinds of deposits without damaging the original protective coatings

SHIP MAINTENANCE

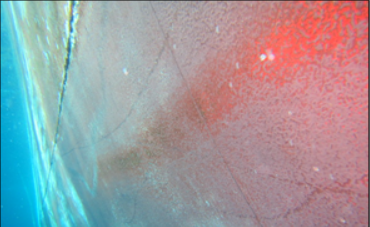

After

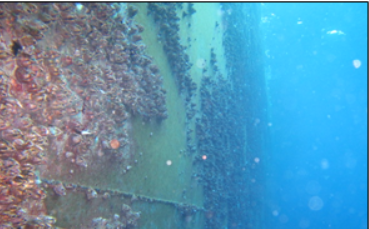

Before